James Boulter, a researcher at UW-Eau Claire, is developing a new device which could improve working conditions in mining, construction, pottery, and masonry professions.

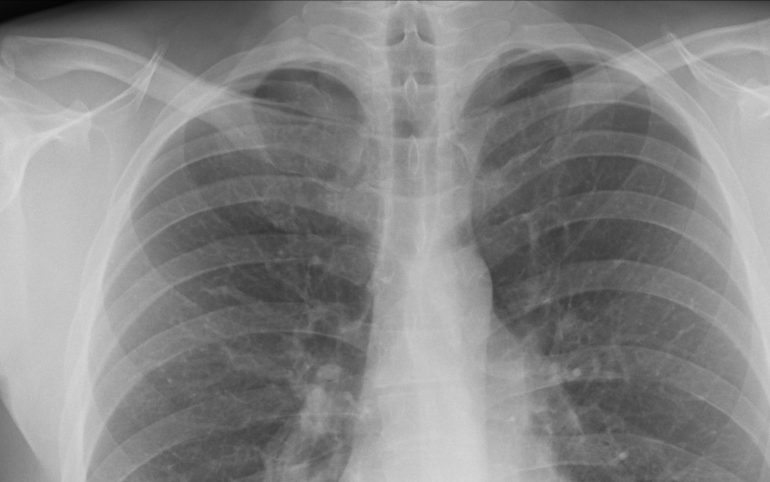

In these fields, workers can be exposed to crystalline silica dust that, when inhaled, can lead to harmful diseases such as silicosis, an incurable and sometimes lethal lung disease, as well as tuberculosis and lung cancer.

The Occupational Safety and Health Administration—the government agency that assures proper safety conditions for various careers—recently reduced the allowance of silica concentration in the workplace.

However, there isn’t a specific instrument readily available to measure silica levels in the workplace.

Although, these analyses are done routinely, they’re generally done offsite and often with significant delays.

The purpose of the new device is to rapidly quantify airborne respirable silica, as well as decrease costs currently spent on meeting safety regulations regarding crystalline silica dust exposure for workers.

The table-top instrument collects air and uses specialized components to collect particles into solution, where it then reacts to form a molecule that can further react to produce light.

A prototype is being created with funding from the Applied Research-WiSys Technology Advancement Grant (AR-WiTAG) that implements the research Boulter and his students performed to develop the chemistry approach that is specific to airborne silica particles.

The initial interest in this project began with an idea from Boulter’s colleague who specializes in monitoring silica levels in various communities from a human safety and environmental protection perspective.

Boulter said this project is a “slight departure” in terms of focusing on commercialization, but he said he is eager to see how the project evolves.